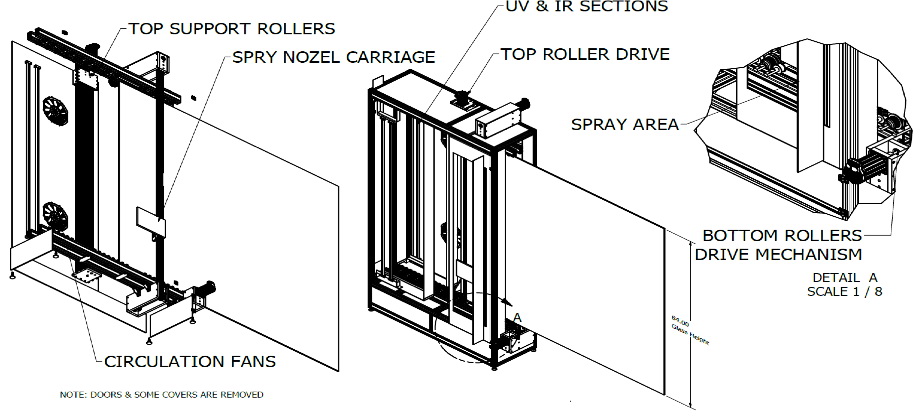

UNELKO Invisible Shield Microburst - V2S Vertical Glass Coating Machine

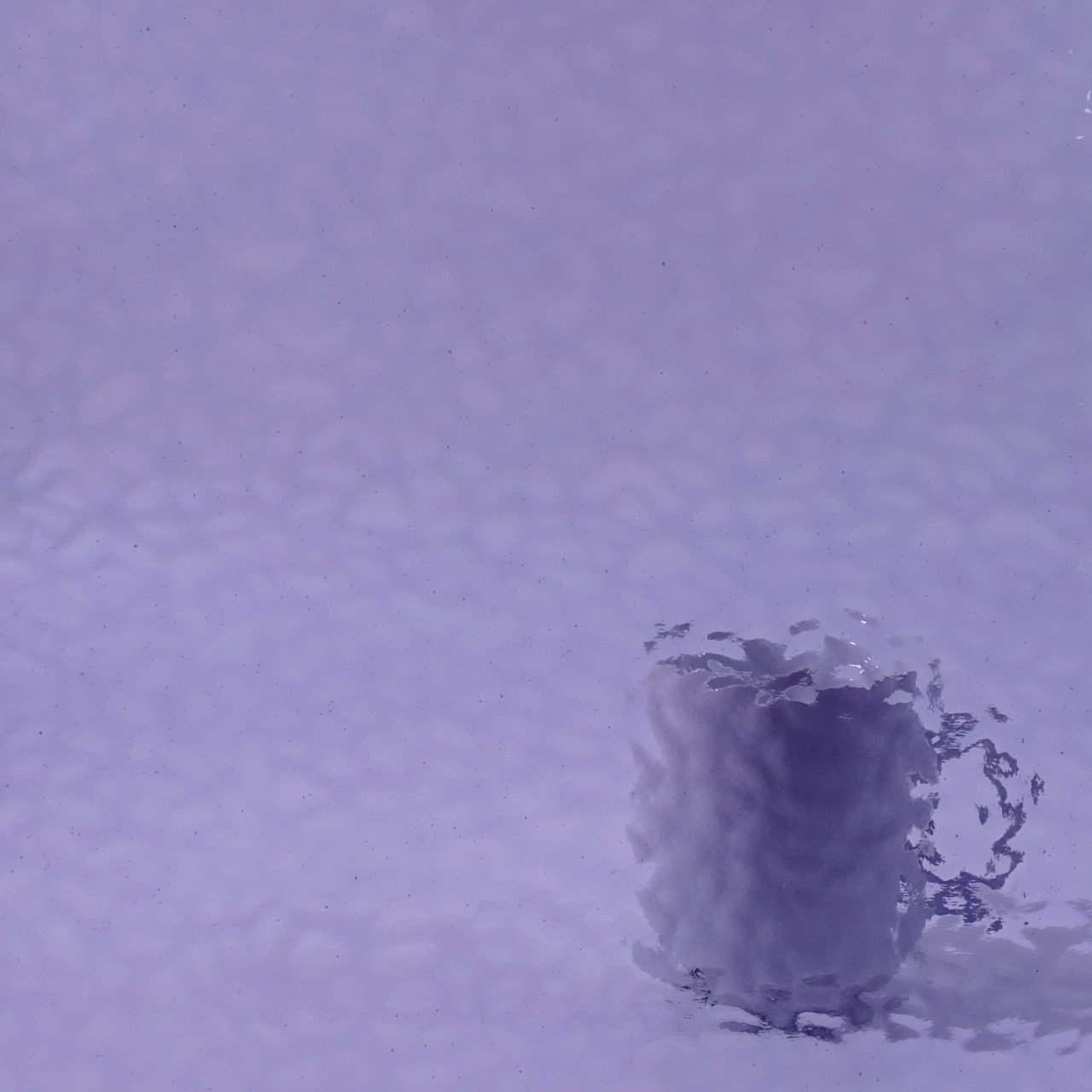

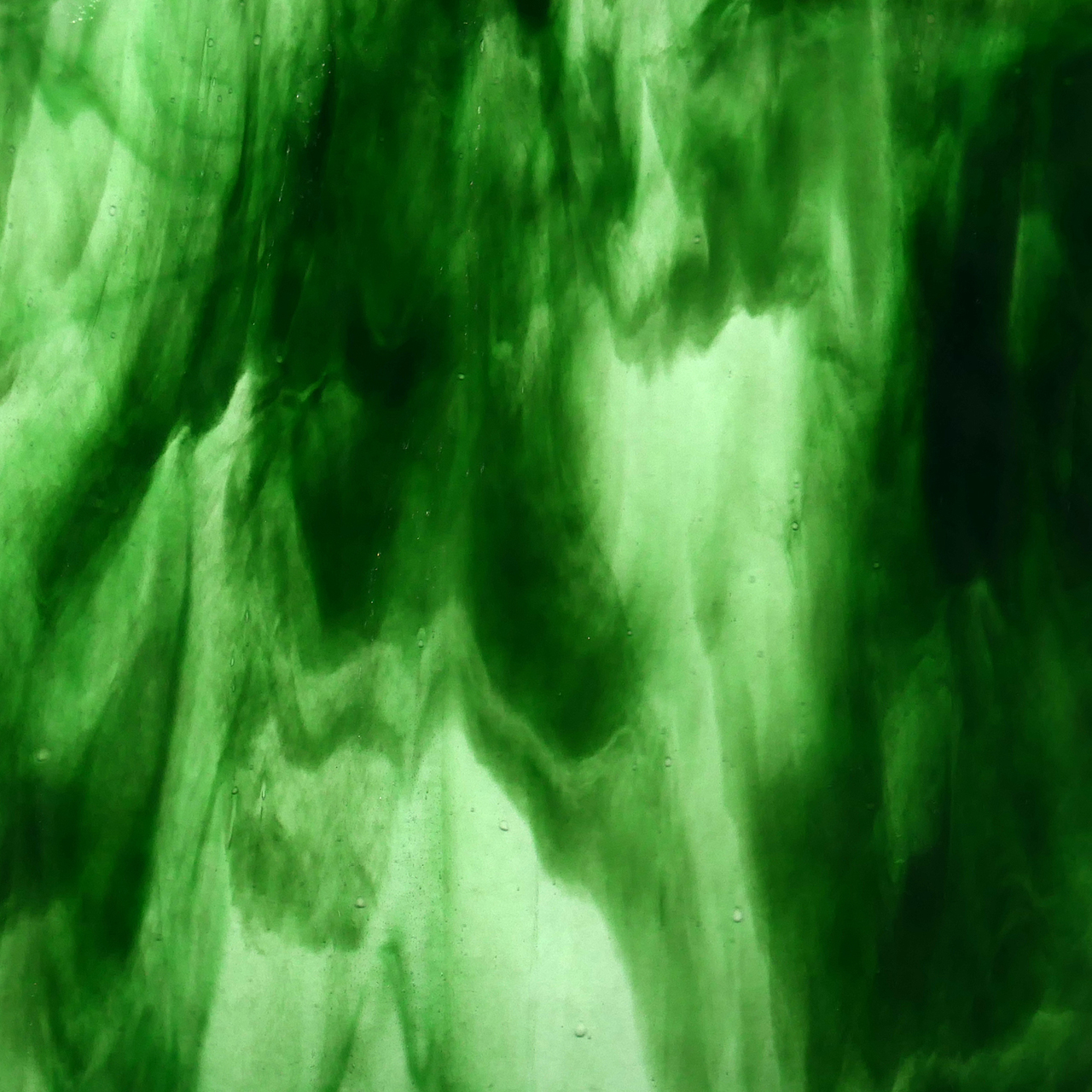

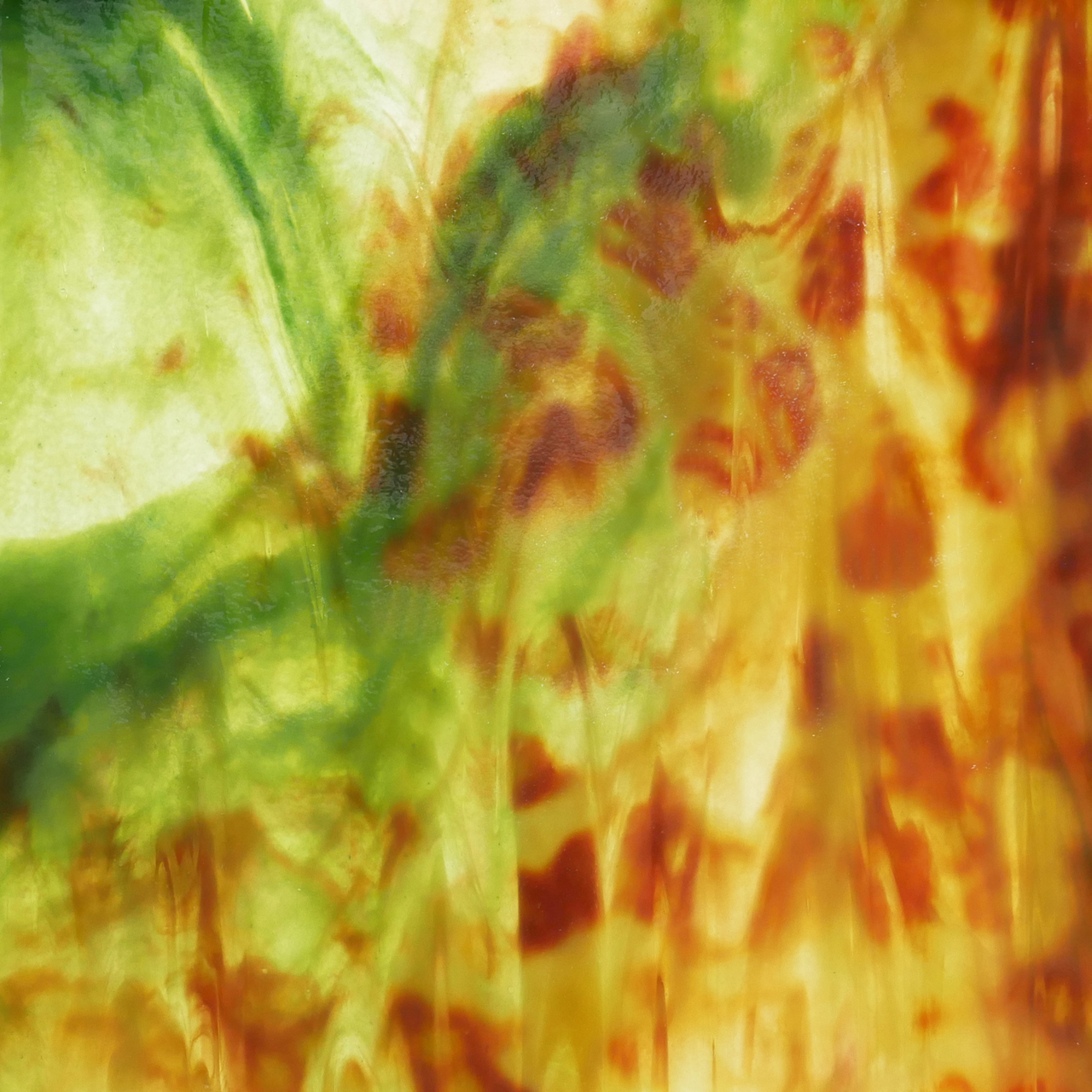

The New Invisible Shield PRO 15 glass coating machine is a compact, high output, two sided automatic coating machine that utilizes innovative UV and IR curing to instantly form a molecular bond and protective coating to all glass. It was designed for glass manufacturers and fabricators that rely on high output, automated systems to produce, fabricate and protect volume shower glass and IG units. Invisible Shield PRO 15 protects glass with a durable Nano Scale hydrophobic coating that seals, preserves and protects glass against water, soil & stains, scratches, pitting and corrosion to keep glass in a "like New" and pristine condition and protected against the elements.

Coating Equipment Benefits

- Space Saving and Fully Automated Coating System

- Durable UV & IR Bonding Technology

- Manufactured to the Highest Standards and Specifications

- Efficient Vertical Design - Compact Adaptable Footprint

- Double-Sided Coating (One sided - disable option if needed to eliminate waste)

- Safe & Fully Vented System

- Touch Screen Controls with Adjustable Feed Rate

- Glass is completely treated/protected and exits the machine clean & dry

- Efficiency - Coats up to 1.2 mtr. (60 inch) Per Minute

- Height Capacity - 84 inches/2.13 Meter of glass treated in one minute

- All Electronics are Explosion Proof with Built-In Safety

Design & Operational Benefits

1. Dual spray heads are integrated within a CNC motion system to provide a precise and uniform spray pattern. Motion control sensors enables the operator to fine tune both the application speed and desired overlap pattern. Operator can override the application speed to increased or decreased speed which is ideal for testing specialty applications. Tow head spray design enhances reliability and significantly lowers spray head maintenance as compared to a stationary volume spray head configured machine.

2.The glass sheets are guided by a V groove and urethane guide roller and rail mounting. Wheel design accepts a range of glass thicknesses requiring no operator adjustment or setup. The upper rail system is CNC software controlled to accommodate the required glass height. The top rollers guides and supports the glass sheet in a vertical position. The lower rollers are servo motor powered to provide a constant speed feed rate. Urethane V groove wheels provide a non-scratch surface coupled with excellent wear characteristics.

3. The curing process of the PRO 15 coating is fast paced by means of both (IR) Infrared heating and (UV) Ultraviolet light bonding technology for both sides of the glass. Glass sheets can be off loaded upon auto feed exit from the machine. To lower operating and maintenance cost the IR and UV elements are activated based on actual glass height curing needs. Circulation inlet fans provide ambient convection cooling of the glass coupled with an exhaust duct fan to remove any residual fumes from the process chamber. The exhaust fumes exit the top of the machine with the ability to connect and route a 4" duct hose exiting through the ceiling at operator's option.

4. The operator console is a standalone enclosure separate from the coating machine structure. This console houses the operator controls and all motion and electrical components. By design, this separation isolates the electronics from dirt, debris, or fume exposure. The console layout provides the operator quick and easy access for troubleshooting events. The cabinet is cooled by a filter inlet circulation fan yielding a positive pressure cabinet; this protects the components from contamination due to any particulates or fumes entering the cabinet.

Control Features

- Glass Feed Rate Adjustment - 1 to 100 inch/min (dial up/down increments of 1%)

- Glass Sheet Height Adjustment - operator selects glass size & thickness, positions to properly height automatically

- Spray Feed Rate - 1 to 800 inch/min (fine tune dial up/down increments of 1%)

- Overlap Spray Distance - default number with operator ability to adjust in 0.1" increments

- Console Main Disconnect Power Switch

- Machine Frame Mounted E-Stop Switch

- Touch Screen Monitor with independent key board

- Screen Touch Switches - cycle start, cycle stop, cycle resume, E-stop

- Screen - proximity switch indications for - glass feed inlet, height calibration, spray calibration

- Machine mounted Air Regular Adjustment

- Spray ON/OFF Override - touch switch to activate manually for priming or adjustments

- Remote Diagnostics Capability - PST tech support

Footprint Dimensions:

Machine Only Height 280 cm, Length 158 cm, Depth 102 cm

Machine with Loading Wings Height 280 cm, Length 523 cm, Depth 102 cm

Glass Sheet Specifications:

Max/Min Glass Thickness 31,8 mm

Max/Min Glass Height 213cm / 10,2 cm

Max/Min Glass Length 243 cm / 61 cm (limited only by loading/unloading support methods, otherwise continuous feed)

Electrical Requirements:

Power Requirements 25,000 Watts

Full Load Amps 230V/120A, 480V/60A

Circuit Breaker 480V/100 amp breaker, 230V/150 amp breaker

Compressed Air: 80 psig @ CFM

Motion Drive System:

Glass Feed Servo Motor/serpentine belt drive

Glass Height Adjustment Servo Motor/screw drive

Spray Heads Servo Motor/belt driven

Curing Equipment/Application:

Infrared red heating (IR) Dual - 4000W Units

Ultraviolet light (UV) Dual - 200 W Units

Circulation Fans Quad - 2 units per glass side

Annual Performance capacity:

405,800 sq/mtr.* (4,368,000 sq/ft) One Sided

811,600 sq/mtr.* (8,736,000 sq/ft) Two Sided

* based on 35 sq/ft per minute (One sided) and 80 sq/ft per minute (Two sided)