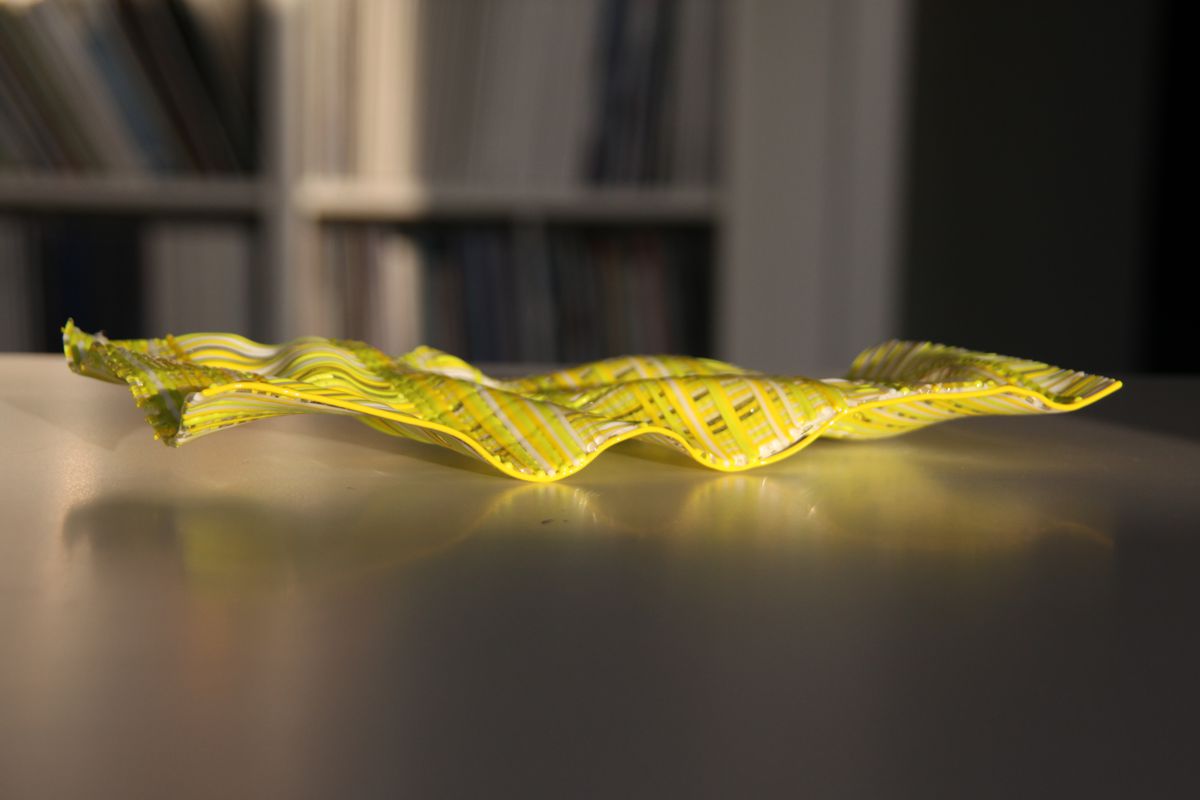

Flying carpet

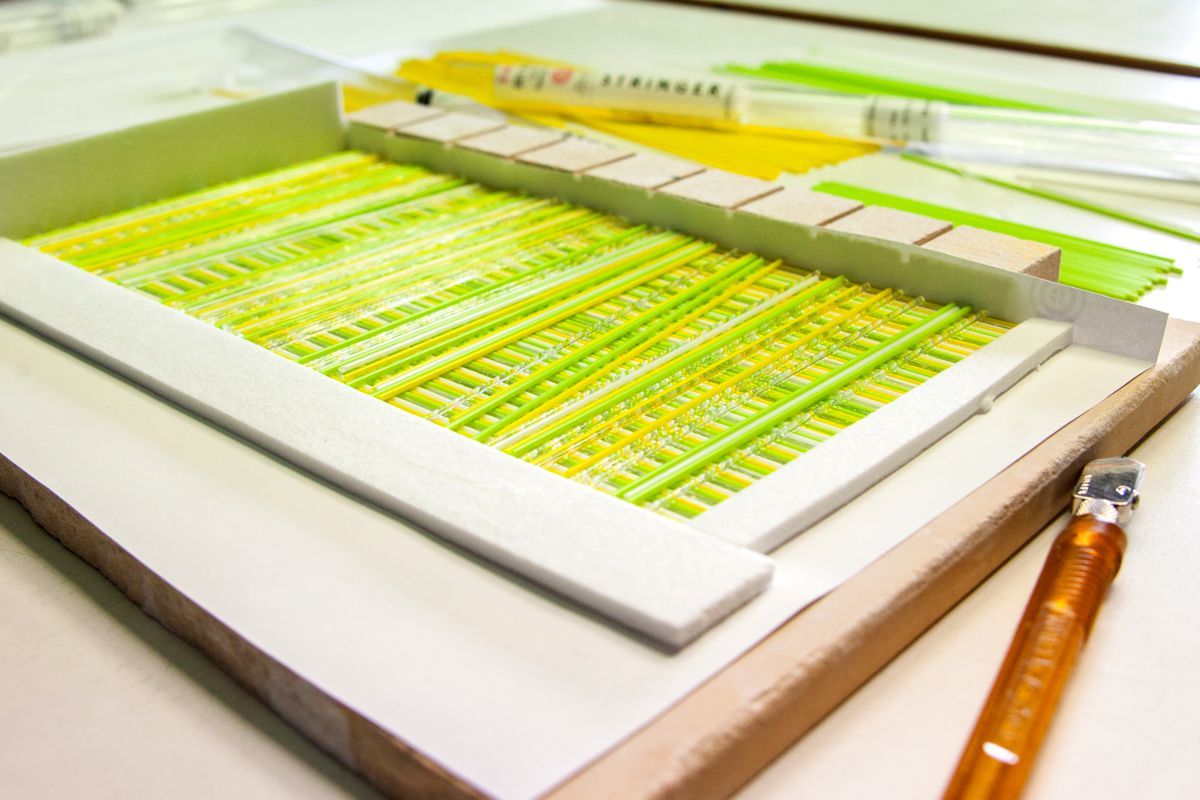

Step 1

First prepare your kiln shelf. Use fibre paper as a base and build a frame from bricks or strips of thicker fiber paper. Lightly hitting the glass threads against the laid paper will keep them from rolling away. Now place the bottom layer of glass threads close together on the fiber paper. The top layer of glass threads is laid across the base layer. The top layers is not simply close together, but have different sized gaps to give the carpet a more natural look. The glass piece in our example is approximately 20x40cm, fused at 770°C for 15 minutes. (may vary depending on klin conditions and colors).

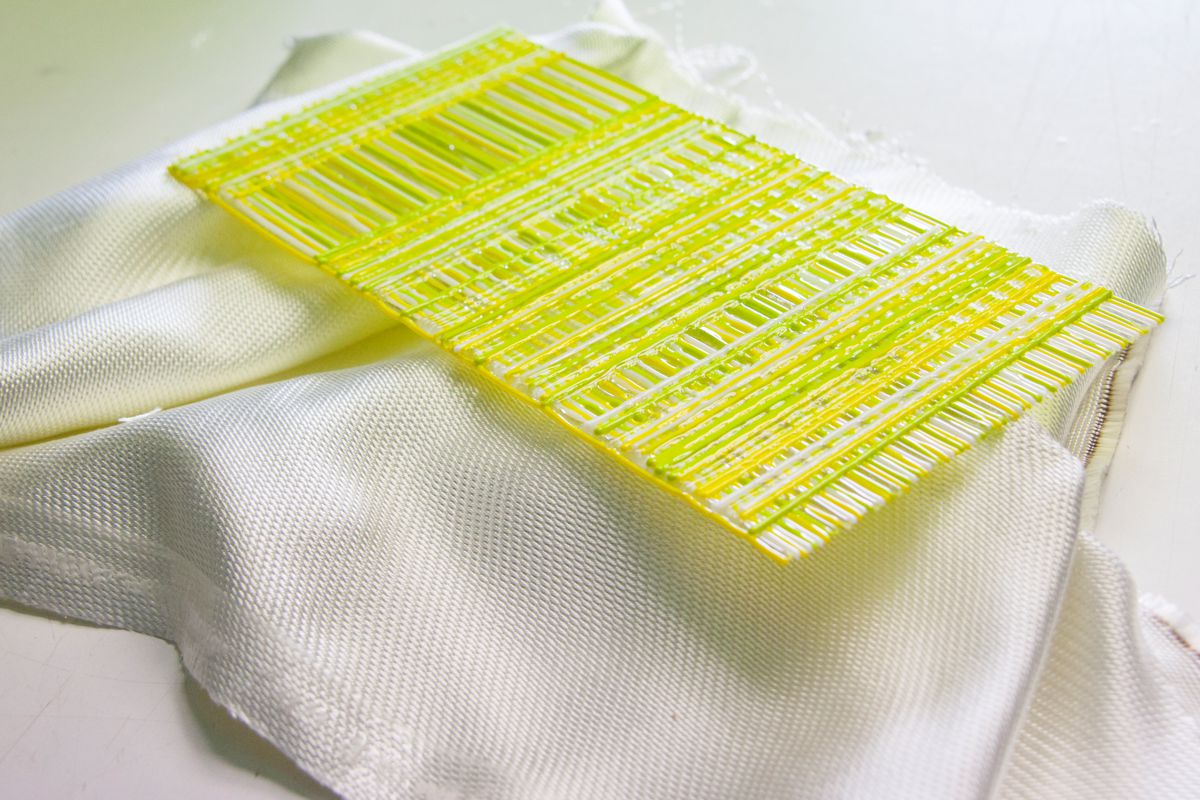

Step 2

In the second step, you now deform the flat pane over a free form of silicatex fabric. Fold the fabric until you get an interesting shape that will make your pre-melted glass pane appear later as a flying carpet. The slumping temperature in our example: 660°C for 30 minutes.

Slumping carpet:

1. 70 minutes - 500°C - 0 minutes

2. skip - 660°C - 30 minutes

3. skip - 520°C - 70 minutes

4. 70 minutes - 460°C - 0 minutes

5. End

Colourful bowl:

Step 1

Take the Patty Gray mold, apply shelf primer all around the inner edges and let it dry. Now place a piece of fiber paper into the mold. With ZAGG-ZAGG mosaic pliers or Nikken glass cutter, cut and break the pieces to a desired shape. Bigger and clearer glass pieces will bring the object to a more transparent effect, smaller and more opalescent pieces will give a darker and more solid effect. You can combine transparent and opalescent glass pieces!

Step 2

Place all the pieces in the mold, make sure they are evenly distributed. When all the pieces are in place, place the mold in your kiln. The heating and annealing will be more even if you place the mold on small supports.

Step 3

After cooling down, take the fusing plate out of the kiln. The shards are melted to an even surface. You can now slump it.

Step 4

Take some pieces of Cerablanket and place them into your kiln. Spread them approximately over the surface of the bowl (30x30 cm), then drape the silicatex fabric over it..

Step 5

Now you can put the glass on it and lower it.

Slumping carpet:

1. 240 minutes - 500°C - 0 minutes

2. skip - 670°C - 30 minutes

3. skip - 510°C - 120 minutes

4. 240 minutes - 430°C - 15 minutes

5. 120 minutes - 375°C - 15 minutes

6. End

More use for Silicatex fabric

Place a piece of it to your lamp bending mold, for example the stainless steel mold 3523000, so you can avoid the boron nitrite coating.

You can also place the mesh in ceramic molds to save constant painting with release agent. In any case, you should prime the mold with release agent as protection, but after that you can just put the mesh on and adjust it.

Use the fabric as a kiln base or on ceramic plates for fusing. CAUTION: it works well with transparent glasses, opaque ones also stick here (as they do to all fiber papers).